find your material.

Our products include nickel, copper, steel, aluminum and ceramic alloys to meet a variety of customer needs. A stringent focus on quality results in parts that are highly reliable and can withstand high-stress, high-temperature operation.

Prime Powders ensures quality and powder purity through regular chemical and physical testing, along with strict oversight at each stage of the manufacturing process.

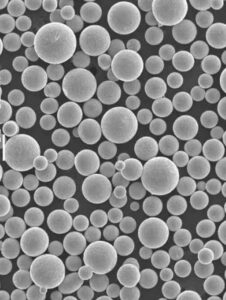

Narrow particle size distribution

Satellite-Free

Near-perfect sphericality

Oxidation resistance

PRIME 625

BENEFITS

A family of austenitic powders that are similar in chemistry to EN 1.4404 and UNS

S316603. These materials are designed for processing in Laser Powder Bed Fusion

(LB-PBF), Electron Beam Powder Bed Fusion (EB-PBF) or Directed Energy Deposition

(DED) additive manufacturing systems. MetcoAdd 316L series products have been

rigorously engineered specifically to meet the demanding requirements for additive

manufacturing.

APPLICATIONS

■ Aerospace: Clamping elements and heat exchangers

■ Medical: Surgical tools and orthopedic implants

■ Transport: Maritime components

■ Tooling: Pressure injection dies and molds

■ Consumer: Jewelry and watch components

properties

| Parameter | Specification |

|---|---|

| Particle size range | 15-45 μm typical |

| Particle shape | Spherical morphology |

| Apparent density | > 4 g/cc |

| Tap density | > 6 g/cc |

| Hall flow rate | >99.9% |

| Oxygen content | <100 ppm |